We headed north to the Bay of Islands, anchoring for a night midway at Mimiwhangata Bay. Don’t get tired of the Mauri names!

WARNING: For those non-yachties, this blog is about the boat maintenance we did in Opua. The next blog may be more of interest!

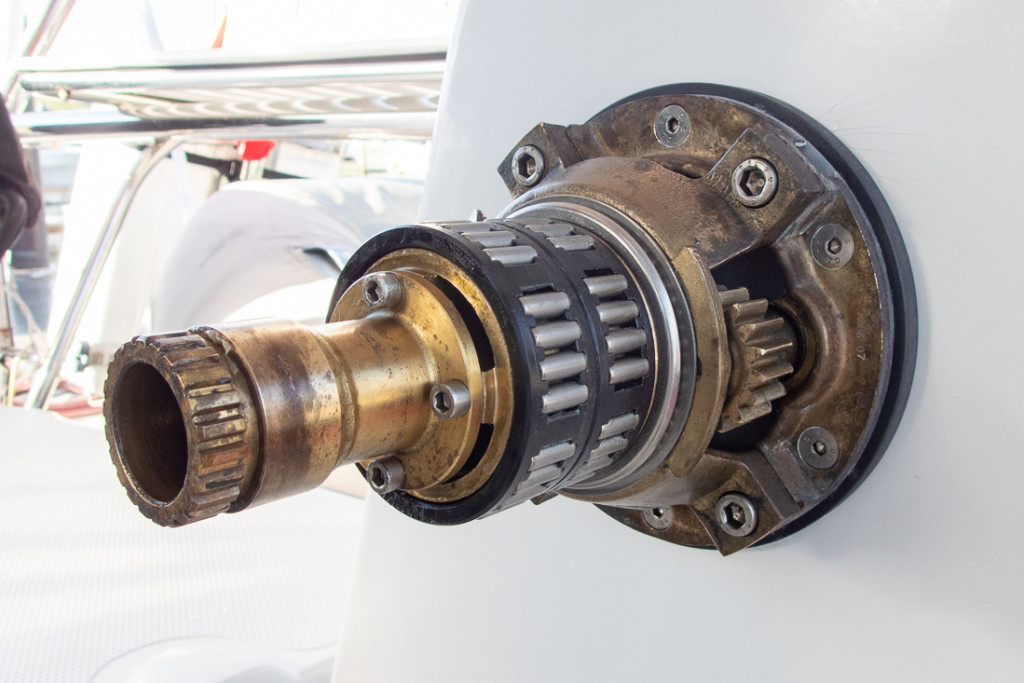

We arrived at the Bay of Islands Marina on a Wednesday and contacted Northland Spar & Rigging about some rigging repairs. They had us in their schedule to start a few repairs recommended in their November rig report. Joe, a new face, removed the upper diamond on one side but Monty had seen a bit of wear on the one on the other side and asked Joe to check it. Joe agreed it should probably be replaced too. Diamonds help to stabilize the mast. The wear occurred where the upper and lower diamonds intersect, and though a chafe guard was in place, the upper diamonds still got a little wear.

Around the same time, we got a response from our insurance agent as to whether we really had to replace all the standing rigging, now 12 years old. The insurance company would cover the boat as long as we accepted a higher deductible for any rig-related damage and got all the other recommended repairs completed. It got us doing some research. We got a rough estimate on complete replacement of the standing rigging and ensured that NSR had the time to get it done in the next couple weeks (before our visitor visas ran out). We decided it was time to go ahead with complete replacement. The existing rigging had served the boat well sailing 45000NM over 12 years. With new rigging, we would have more confidence in our rig, not be second guessing what components had been replaced when and, hopefully, the insurance company would hopefully be happy for another 10 years.

We had also lined up Hans Klomp (Tuahara Electronics) to come have a look at our radar unit which had stopped rotating for 3 days on our last passage. He had done the installation of the unit in November, 2016. He went up the mast and checked inside the radar dome. He then did a couple software updates. One update gave an error message at the end so he decided to send it to Auckland for further testing, under warranty, fortunately.

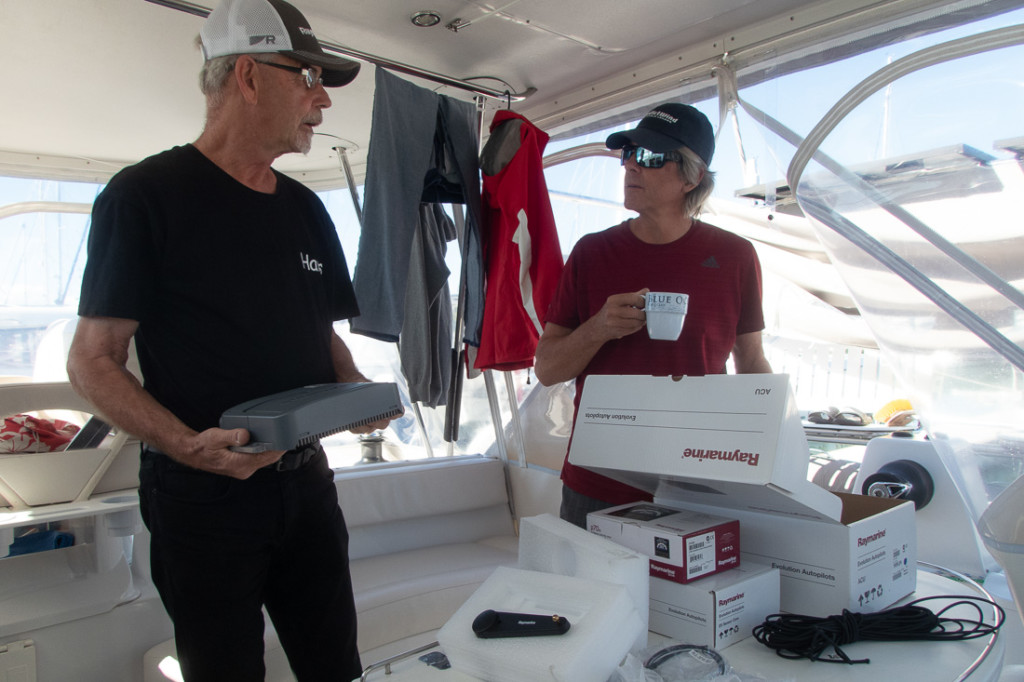

He also checked the autopilot as it had stopped working a few times, without any alarm. We showed him the error messages logged on our chart-plotter. He gave us bad news. It was probably time for a new unit. We asked for a quote and decided to take the weekend to think about what we to do.

He installed a VHF remote at our nav-station so we can use the radio without having to go to the cockpit.

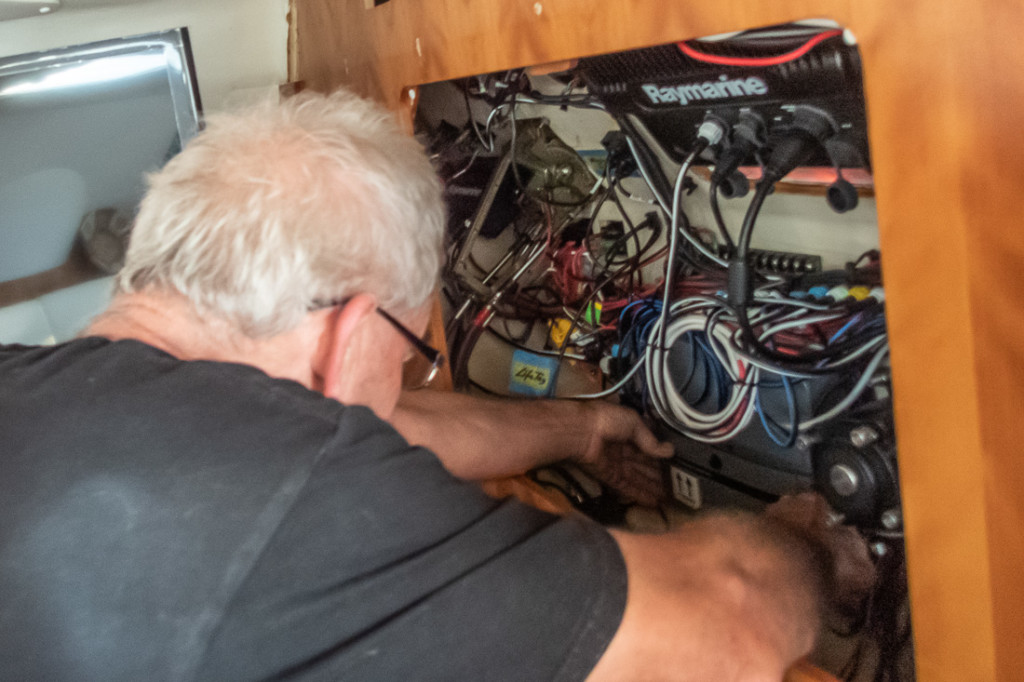

Offshore cruisers like us rely heavily on their autopilot. We didn’t want to be on our way to Tonga or some remote place and have it fail. We asked Hans to order a new pilot. It is really “the brain” that he ordered but it comes with a new flux-gate compass and rudder reference, even if you don’t need them. He installed it later in the week.

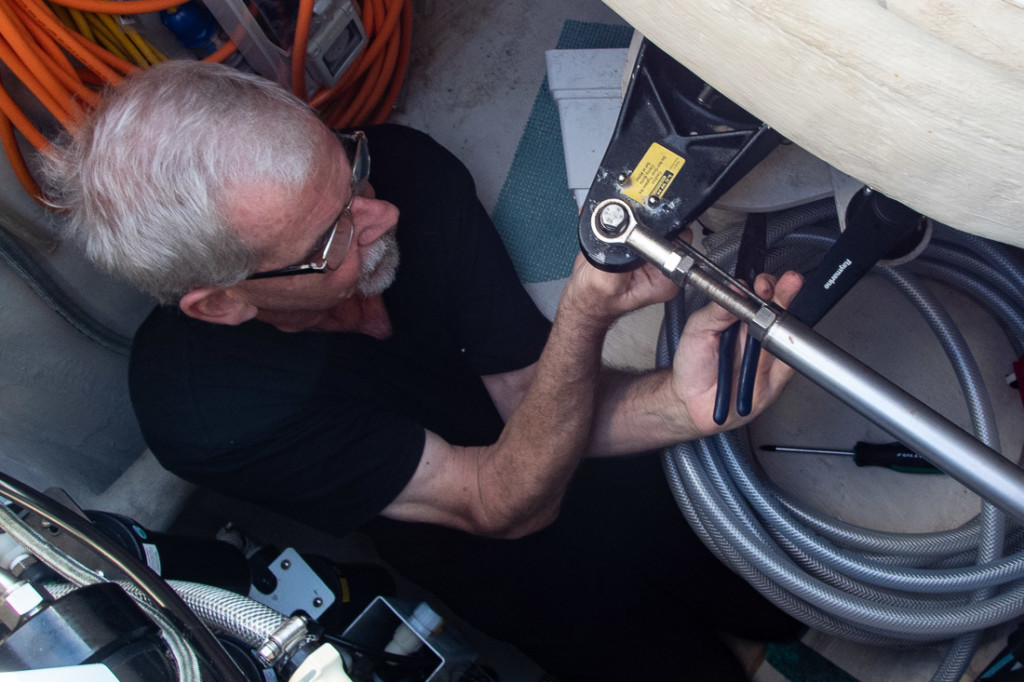

In the process of adjusting the rudder reference, Hans noticed a missing screw and one rusty screw needing replacement, which he addressed. A good thing!

He also replaced the fluxgate compass. We would need to get out of the marina and allow the unit to complete its calibration. We would then need to test it.

We had purchased a new GPS unit in Fiji a year and a half ago, as the old one had died. Wiring the new unit was a daunting task, and the Fijian electrician didn’t really have time to help us. As our chart plotters each had a GPS unit as well as our AIS, we really didn’t need it. We left it in a box. When Hans was there installing all this other equipment, we thought we might as well ask him to help install it. They opened up the ceiling and had a look around. The wires had to go up through a support pole and then make a right turn. The old wire was not much use as it was stuck at a corner, but Hans was the right guy to get the job done. He persisted and after a few hours, got it set up.

Meanwhile, the rigging replacement was moving along.

The winches sound so nice after the maintenance!

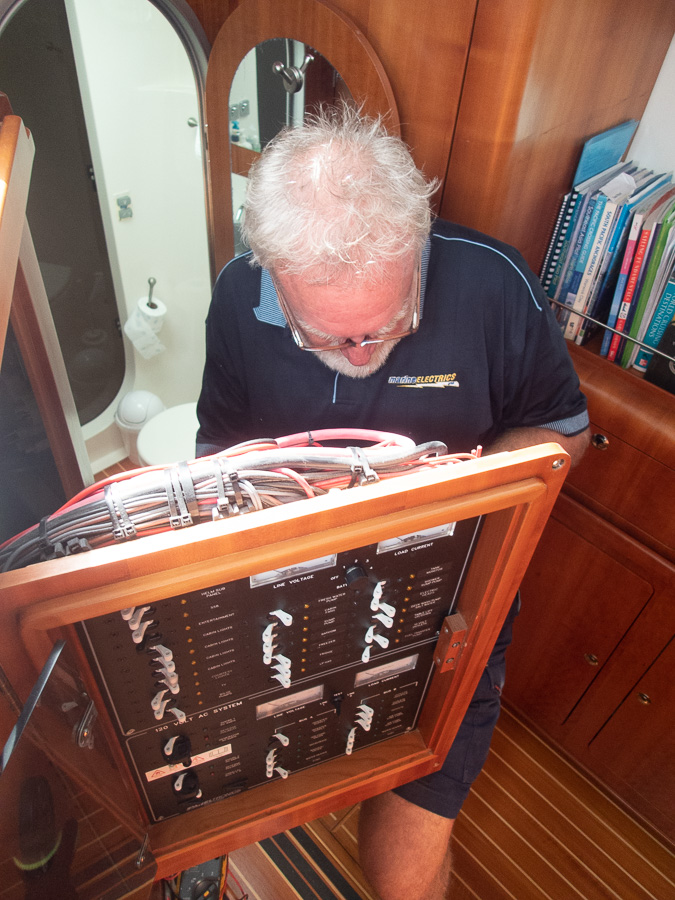

Rob from Marine Electrics did a little electrical maintenance including replacing an element in one of the hot water heaters and having a look at a switch on our electrical panel.

We got out for a weekend of sailing to put the new rigging under load and test the new autopilot and check the radar.

When we got back at the marina, Monty was going to do an oil change and found some oil in both bilges which was quite unusual. Upon some investigation, a plug had popped out of each engine. It was the plug for the secondary oil dipstick hole. It was very odd that it would happen to both engines on the same weekend. Maybe it was all the bouncy around we were doing in the bay putting our rigging under some load! Both plugs were old and dry and not fitting that tight, so new ones were ordered. Waiting for them to arrive held us in town for over a week as the plugs were coming from Melbourne and Anzac holiday interrupted the normal delivery timing. The delay caused us some concern, as a weather window was opening up. But we got them just in time.

We checked the expiry dates for our flares and fire extinguishers.

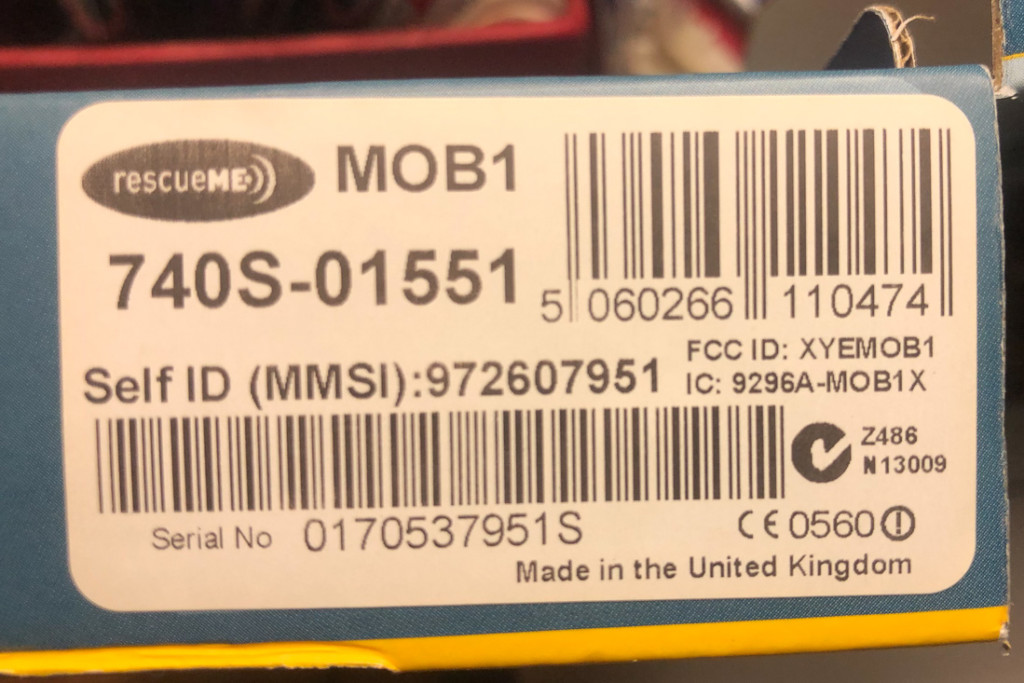

We decided to buy 2 RescueME MOB1 devices. It is fitted on our personal flotation device (life vest). If one of us goes overboard, the device triggers an loud alarm and it shows up on our chart plotter and AIS display. All ships in a 5 mile radius will receive the Man Over Board alarm on their AIS or Chartplotter. It also follows the MOB and keeps updating the person’s position, making it easier to be rescued in heavy seas. We got the registration process completed, the devices activated and installed them on our lifevests.

Congratulations! For those readers that stayed with this, well done! Hopefully you will find future blogs more interesting and fun!

4 comments

Hi M&M, Do not despair … at least some of your readers enjoy reading about what is happening behind the scenes to allow all the beautiful travel blog stuff to happen!! Enjoyed the post! Brad

OMG… Making us remember and feeling better about our little boat bill we paid yesterday for our little boat..

That’s a lot of work ! Nice chafing gear on the boom Monty !

Hi Margy, Serious amount of work and detail involved there! Loved this blog even though I’m not sure I understood a great deal. We miss you at Shaughnessy a lot Margy..do lets try to get together sometime this summer or Fall when you are back in town. Our son Chris is getting married this summer; lots of excitement and visitations from overseas family… Cheers!

Hi Margy and Monty, It looks like you had experienced service technicians, which makes a big difference. I am glad it has all come together well. Happy sailing!